Measurement

Ultrasone Tio Measurement

• Single BA

[1. Frequency Response ]

Raw (silicone eartip)

Diffuse Field Target Compensated

Olive Welti Target Compensated

[2. CSD ]

Uncompensated

[3. Harmonic Distortions ]

• 94dB SPL @ 500Hz

[4. Minimum Phase ]

[5. impedance ]

Black: Impedance

Green: electrical Phase

[6. Square Wave ]

• 300Hz

• 30Hz

[7. Frequency Response of Stock Foam Tip ]

Raw (stock foam tip)

Diffuse Field Target Compensated

Olive Welti Target Compensated

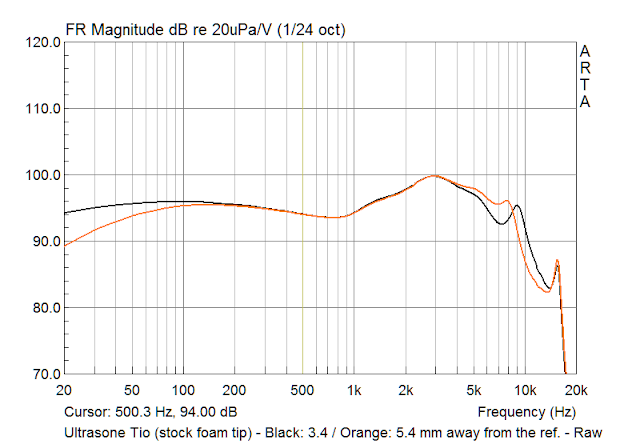

[8. Effect of Insertion Depth ]

Uncompensated

Stock foam tip

• Black: 3.4 mm

• Orange: 5.4 mm

Away from the reference plane

[9. Effect of Resistor ]

Uncompensated

• Black: 0

• Blue: 10

• Orange: 30

• Yellow: 90

• Green: 300

Ohm resistor added

I just bought a Ultrasone Tio, and I tried to tune it to fit olive-welti target according to your suggestion on the post (Ultrason Tio - Turning Recommendation).

ReplyDeleteI removed the filter, and I am using stock comply form tip. However, I do not know what kind of form piece do I have to insert in the nozzle. Can you please give specific direction about the second step, which is "form piece inserted in the nozzle?"

What kind of form tip do I have to buy? Where can I purchase it? How much do I have to insert in the nozzle?

I'm sorry to bother you. Please give me the direction when you are available.

I just used the normal foam pad.

Deletehttps://goo.gl/ozl26O

Cut this foam pad to suitable size to fit the nozzle tightly.

Thank you for the quick and kind reponse.

DeleteI bought the form pad, and I tried to fit it in the nozzle.

But, I am not sure what I did is right or not.

I cut the form pad in rectangular shape (2cm x 0.5cm) and roll it to become cynlider shape. Then, I put it in the nozzle.

Is it the right way?

Yes but that is too big, I think.

DeleteJust cut that to 0.5cm×0.3cm and insert that piece into the nozzle. You don't have to fold or roll that.

Thank you so much.

DeleteIt sounds much better when the size of inserted form is reduced as you suggested.

I'm sorry to bother you, but I have one more question.

What do you mean by "fit the nozzle tightly?" I am asking this because when I insert the form, there are two cases.

When it comes to the length of the nozzle, the form fills

1. first 2/3 (from the surface) of the nozzle (under the form, there is about 1/3 depth which the form can be inserted) or

2. last 2/3 (from the bottom) of the nozzle (above the form, there is about 1/3 depth which the form can be added)

IMO, you don't need to adjust the foam too detailedly like that. Both would be fine and their sound won't be different with one another.

DeleteOr you can cut the foam piece again to bigger size; for example, 0.7cm×0.4cm. But actually, that little difference won't affect the overall sound signature.

Thank you for your detail and kind advice.

DeleteI am glad to learn from you.

Glad I could be of help.

Delete